|

|

|

|

|

|

Home | Company

History | The

Office Building | Recollections | Family History | History of Firebricks | The Restoration Project | Conserving

Historic Buildings

|

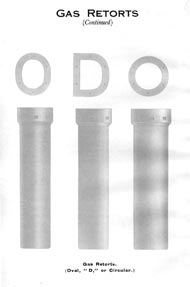

| The History Of Fire Bricks (Contributed by John Cooksey)"The Most Important Industry in the World" The technical name for firebricks is refractories, of which a firebrick is one specific type. It is worth considering that without refractories no other industry could have existed. Somewhere along the manufacturing process of every product refractories would be involved, and that is the same today. The only change is the type of ingredient used to make the shapes, blocks, or bricks, from fireclay, to basic rocks, and the need for this is the change in furnace design and higher temperatures needed for longer periods of time. The refractories industry shaped the way the Industrial Revolution progressed, from bloomeries to iron and steel works, from Cylinder Glass to Pilkingtons float glass furnaces, from the Rocket to the main line steam locomotives, from disease to Henry Doultons salt glazed earthenware pipes, from oil lamps to William Murdochs gas from coal experiments, and so it goes on. Harris and Pearson's brickyard was one of several dozen that made what can be termed standard items from the best fireclay that could be found. They were making retorts, pressed bricks, and wirecut bricks, items for glass works, items for steel works, and many more trades, but so were Homer Hill works, the Delph Works, Amblecote Works, John Hall Refractories, Harper and Moores, Timmis, Himley Fire and Red Brick Co. Some of these yards did make certain items that the others made a few of: the Delph made Grate Backs; B. Gibbons Junior of Gornal specialised in Gas works refractories and at one period in time were the largest in the world; Henry Doulton, in the late 1840s, was again the largest producer of salt glazed earthen pipes in the world employing some 700 people. Glass house pots were made by one or two works. Their makers were skilled people, but equally so were the men that made gas works retorts. These were much larger than glass house pots, and required as much skill. Weighing in excess of a ton, retorts also had to be man-handled into special kilns, because these vessels could be ten feet in height or over. |

|

John Cooksey's Book |

© Copyright WMHBT